Special Feeder

MESE – “concepts & solutions that matter“

Feeding and separation of complex components

Our portfolio in the field of feeding systems ranges from simple applications to complex feeders for placement lines and assembly systems – we offer solutions for a variety of industrial production areas in a wide range of industries.

With our expertise in conception, design, manufacturing and integrated software applications, we develop and manufacture special machines for individual manufacturing processes. Intelligent sorting and feeding systems to automate your production process are the result.

Your component and your production requirements are the foundation of our work.

With our special feeders, the feeding and provisioning of components of all kinds can be realized!

MESE – Your Partner for Special Feeders

Punch Feeder

Bulk Feeder

Punch Feeder

Processable components and their properties

The possible applications are manifold and are developed to fit your production process and the components to be processed. Thus, Odd-Form components made of various materials, alloys and surfaces can be processed and finished. It does not matter whether the components are made of materials such as steel, aluminium, copper, or alloys such as Inox. In addition, it is possible to process components with various surface coatings, such as galvanic or chemical tinning, silver, gold or nickel.

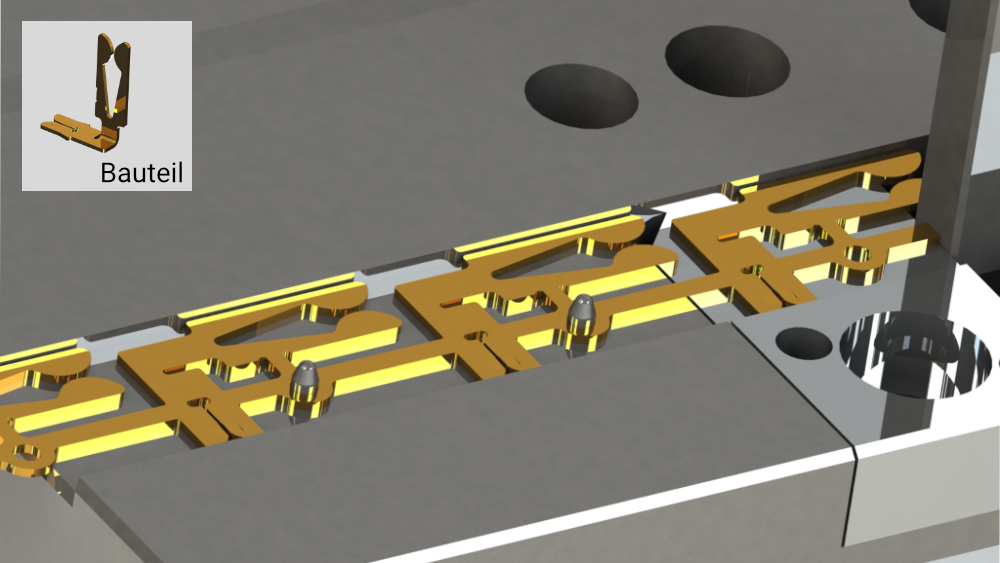

The nature and use of the components can be just as varied as their properties. These can range from punched plates to axial THT components, radial THT components, SMT components packed in blister packs and components connected to carrier strips, such as terminal contacts, socket contacts, and reeds. Furthermore, the processing of cable bridges and electrical wire connections is also possible.

Processing options

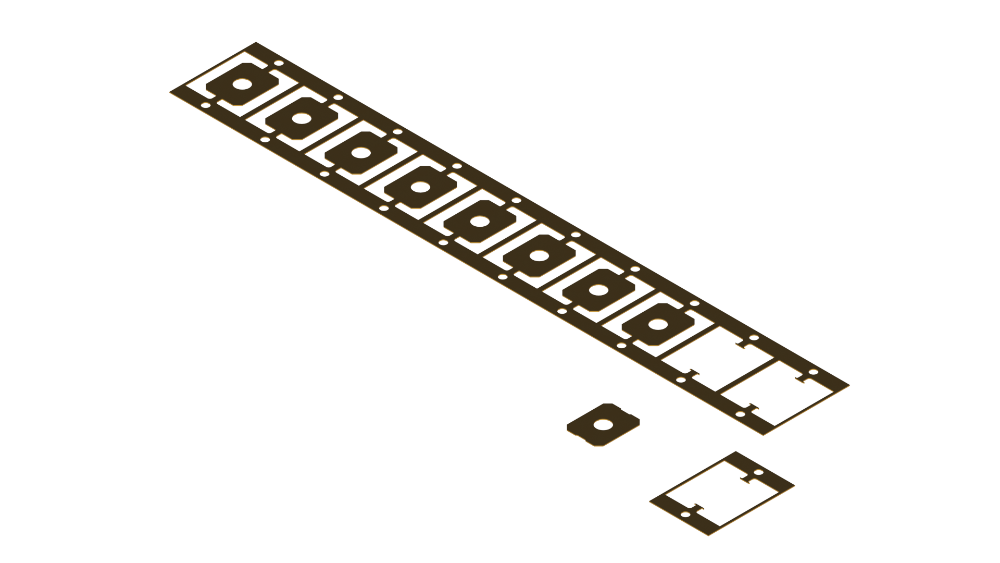

Exemplary, two different starting products for individual processing options are shown below.

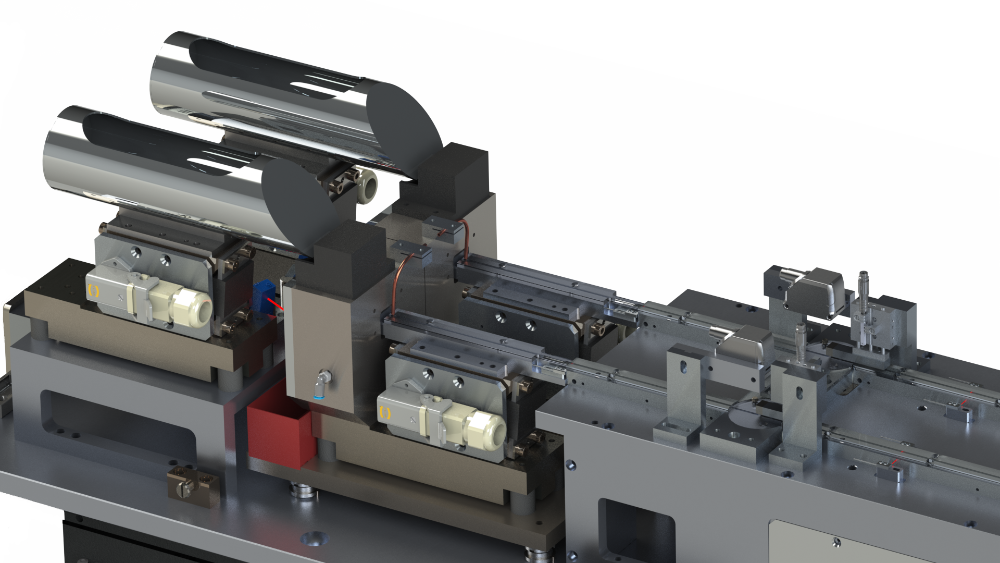

Components punched out of carrier strips

For example the starting product for the production is a carrier strip with enclosed metal plates (soldering and welding plates), which are separated from their carrier strip by the punch feeder and made available for pick up by the pick and place machine. The original product and its carrier strip are delivered on a reel.

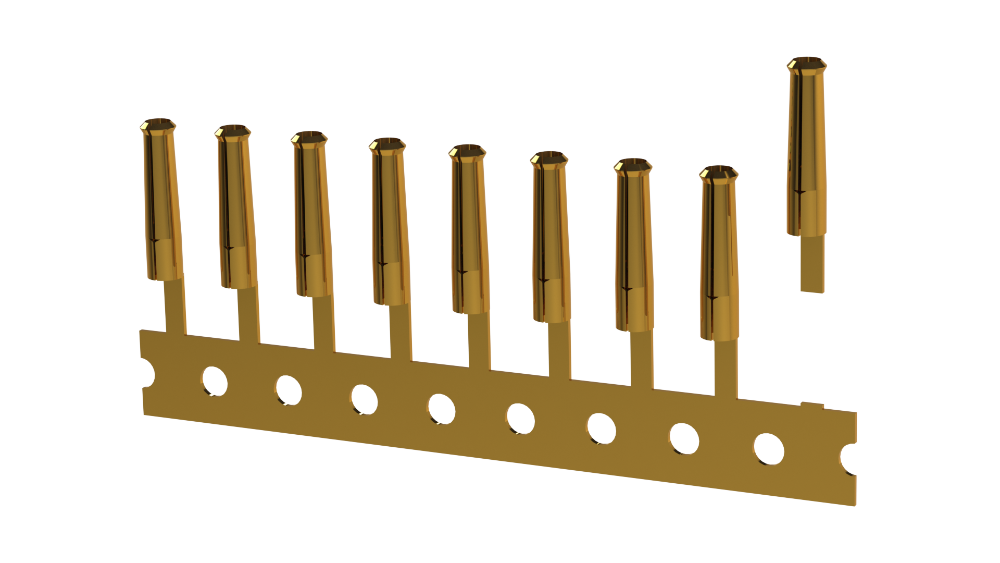

The components are “socket contacts” or other components to be processed, which are connected to a carrier strip and are separated by the feeder (special machine) and fed for further processing.

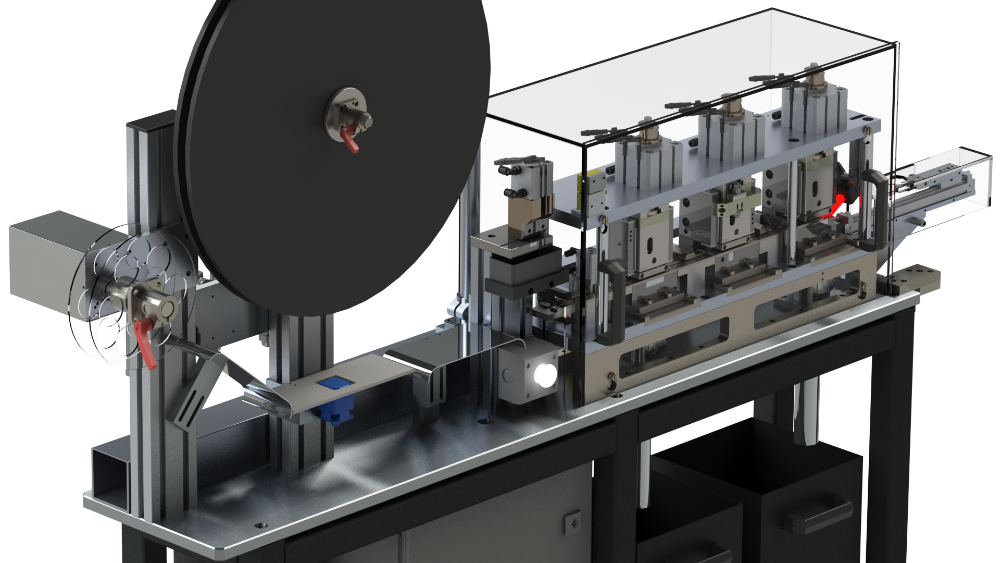

Punch Feeder – an example of a realization

Complete special feeding module for contacts on reel with reel holder, product feed, punching, bending, and cutting tools as well as transfer module for supplying the punched and transformed IDC contact to a downstream production line. The feeding system is equipped with its own control unit, control software, actuators, sensors, and communication interface to the higher-level control system.

Bulk Feeder

Processable components and their properties

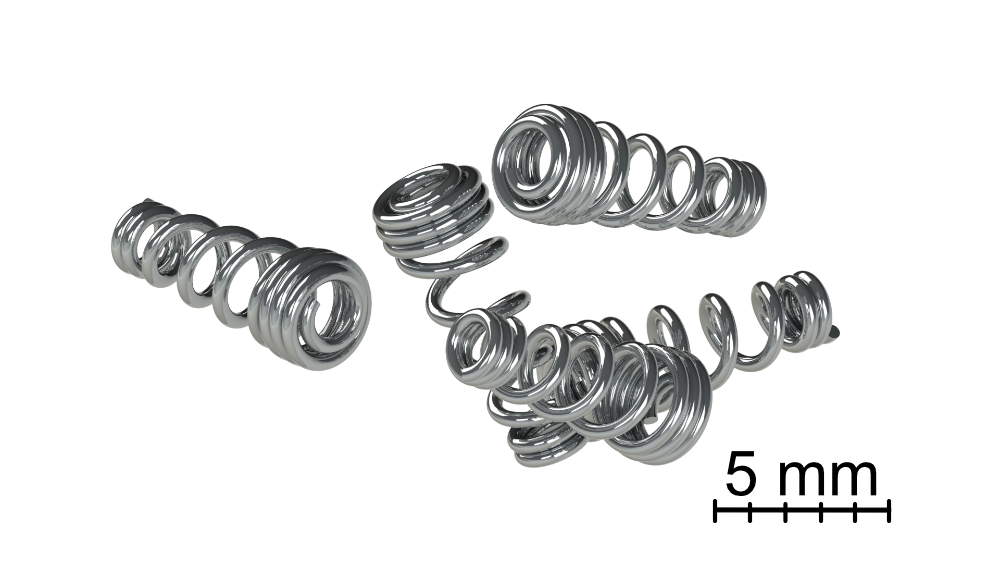

Bulk material is defined as components that are not connected to a carrier strip or placed in a blister and are therefore present as loose piece. Our bulk feeders are optimized for the correct positioning and individual provision of these components. These include springs, pins, sleeves, contacts or bent wire parts.

Depending on the type and condition of the parts and components, different conveying systems and combinations thereof are used. These include spiral conveyors, linear vibratory conveyors, drum, and vortex chamber conveyors.

Processing options

Exemplary two starting products with different product properties are shown below.

Swirl chamber conveyor

Swirl chamber conveyors are particularly well suited for disentangling of components, such as springs, which can easily become entangled.

Our in-house PCCS technology is perfectly suited to transport components that require low throwing heights. These include very flat (starting at 0.2 mm) or small components (e.g. solder balls with a diameter of 0.25 mm), which would stack on top of each other at greater throwing heights.

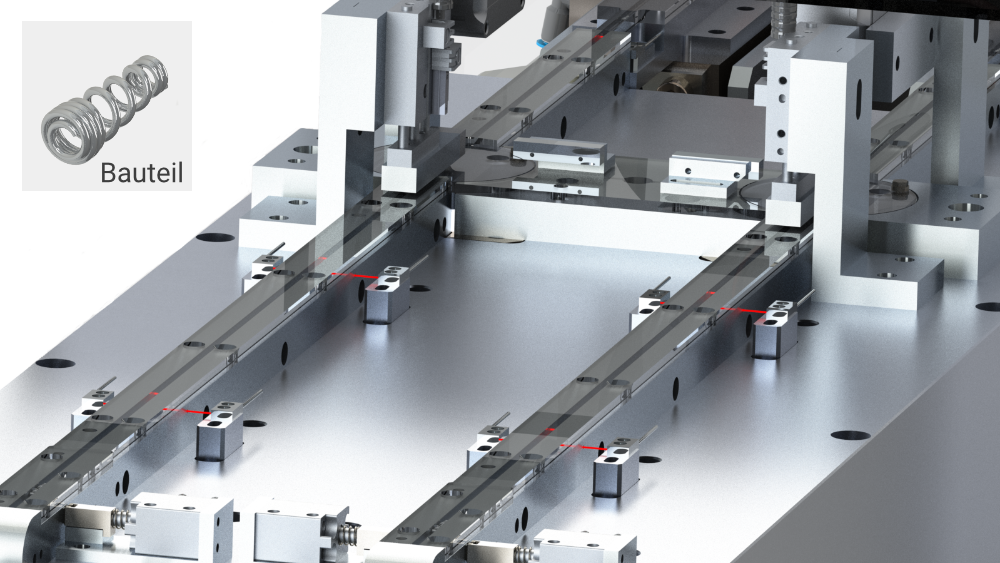

Bulk Feeder – an example for a realization

Specialized feeding system for conical helical springs, spiral springs or contact springs to separate the products and to provide them in the correct position for further processing. The starting product is provided as bulk material.

For example, the springs are provided as bulk material in packaging units of 10,000 pieces. The type of provisioning depends on the cycle time specification per single use and the further production process.

Profit from our know-how

Your experts for individual automation – Special Feeders by MESE.