Services & Maintenance

Our Services at a Glance

For our customers we continually aim for individual and efficient solutions. Thus, with each step, the production can be made even more efficient by using tailor-made automation and specialized machines. Get acquainted with our range of services.

Mechanical

Electrical

Software

Engineering

Mechanical

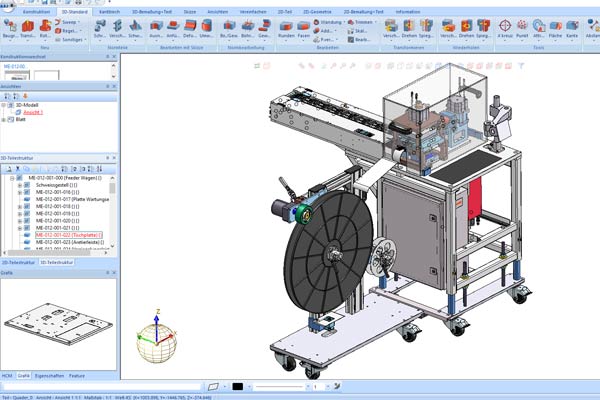

Mechanical Construction

Would you like to increase your profitability or optimize your process reliability? For goals like these and many others we develop solution-oriented concepts. These concepts are implemented with our know-how in design and single part production.

Manufacturing and Procurement

We take care of the handling regarding the entire procurement process to guarantee a smooth running of the project.

For manufacturing we work together with selected partners. These partners always ensure the desired quality. To guarantee a fast response time reworking and adjustments are carried out in-house.

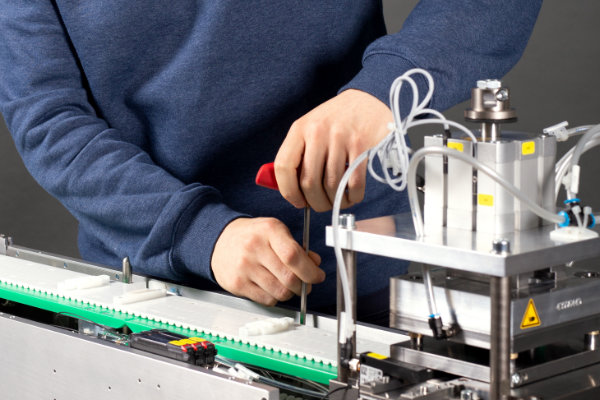

Assembly

An integral part of our work is the assembly of the machines and production lines which we developed for you. We assemble our own developments as well as developments from other companies.

In this process our know-how allows us to gain a comprehensive understanding of the correlation of the individual components.

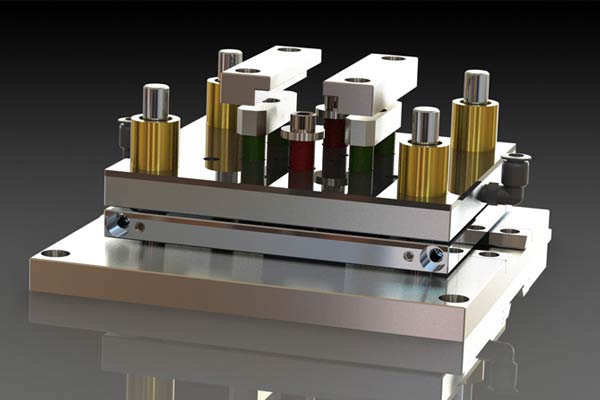

Toolmaking

We manufacture and develop customer-specific and accurately fitted solutions.

For your machines we provide maintenance and repair including spare parts supply.

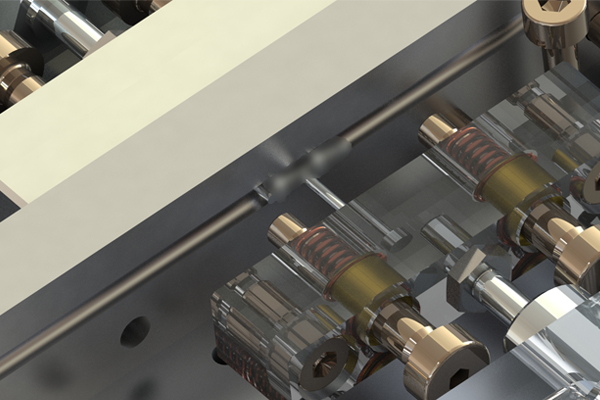

Precision Mechanics

Precision mechanics is one of our special fields.

We design and manufacture precision parts for machines as well as precision mechanical devices.

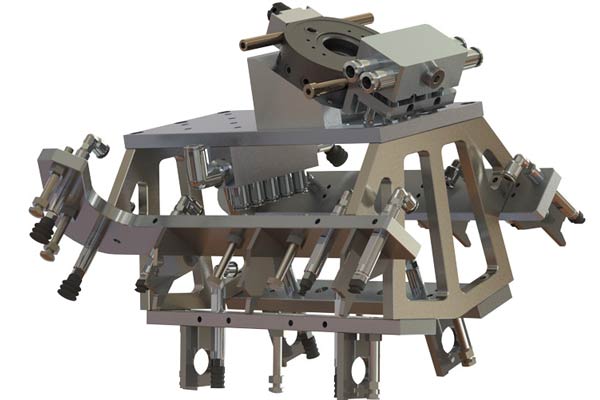

Fixture Construction

We develop and manufacture jigs for manual and semi-autonomous manufacturing processes to optimize your production process.

Apparatus for prototyping as well as sampling and small series production complete our portfolio.

Electrical

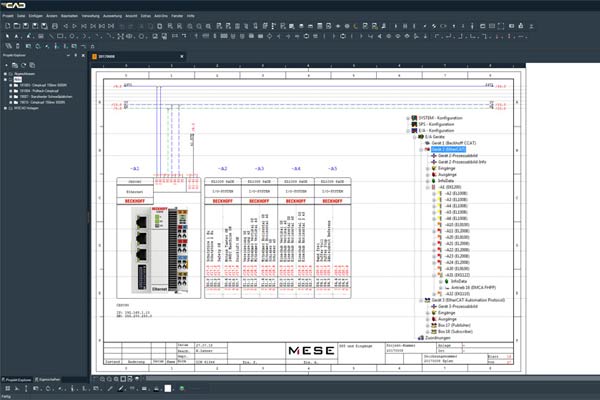

Electrical Construction

We realize electrical constructions according to DIN EN 61346 and electro-pneumatic constructions according to DIN EN 12192.

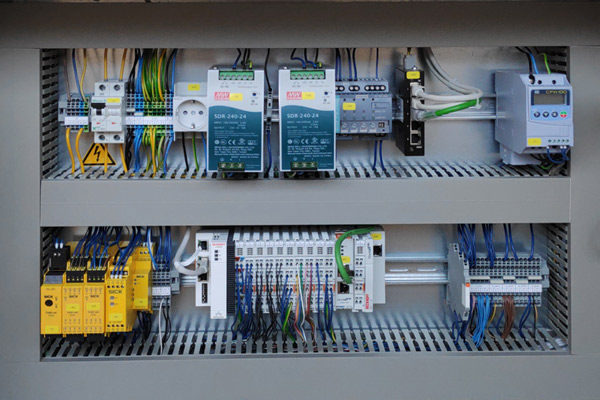

Control Cabinet Construction

We know the latest state of the art technology and implement control cabinet construction in an industrial-conform and demand-oriented manner.

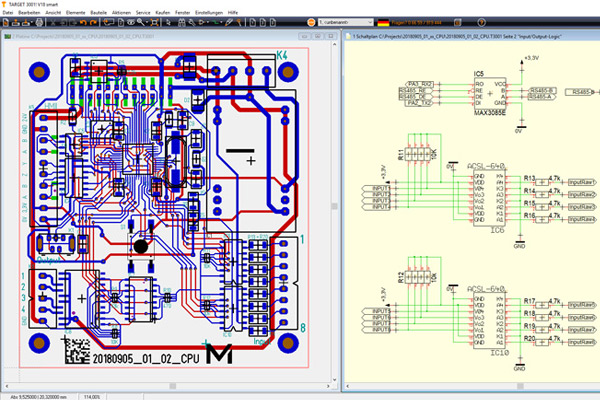

Microelectronics

In the field of microelectronics, we implement highly specialized solutions compliant to the industry standards:

- Small form factor and special requirements

- Well thought out circuit diagram creation

- Simulation of analog circuits, e.g. with LTspice

- Layout of the circuit boards

- Mechanical integration already during CAD-construction

- Our standard components stand out due to their durability and adaptability

Measurement and Control Technology

- Self-optimizing control systems

- Sequencial control with and without sensors

- Integration in HMI (Human Machine Interface)

- Monitoring systems

- Expansion and integration into existing control electronics

- Integration of new technologies

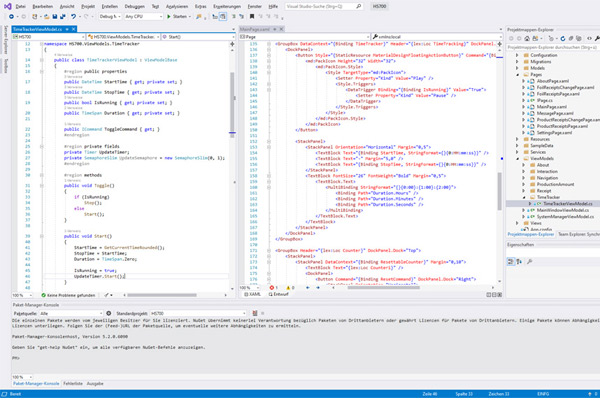

Software

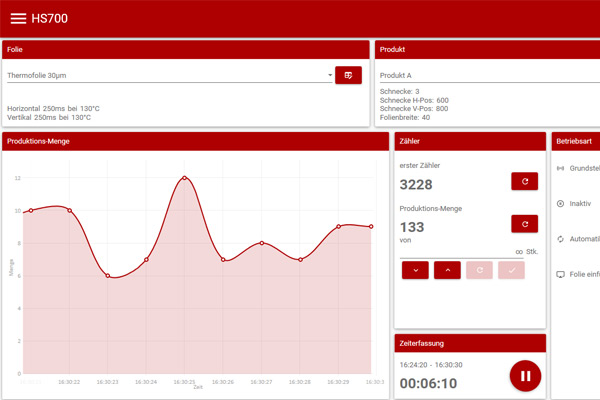

HMI Software

We create HMI software for process automation accordingly to industry standards (e.g. Siemens) or based on our in-house HMI framework. During this we take multilingualism and a modern look & feel into account. Visualizations complete the interface between human and machine.

Application Development

- Concept

- Software Architecture

- Development

- Deployment (Software Distribution)

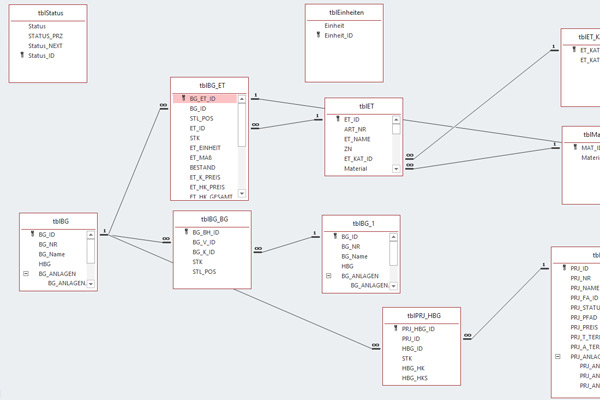

Database Creation

- Database Modeling

- Normalization

- Maintenance

of relational databases and document-oriented databases.

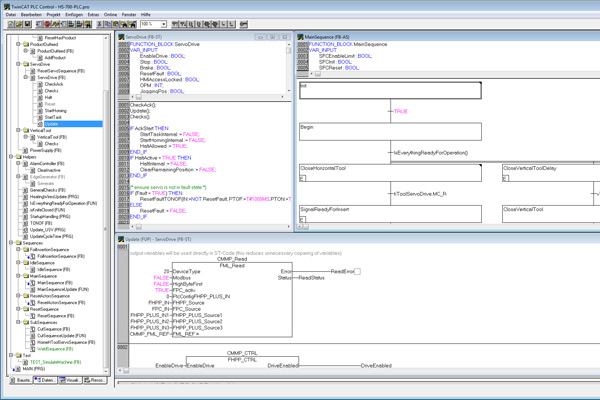

PLC Development

When developing PLCs we do not limit ourselves to individual manufacturers. Therefore, we can offer you economical solutions serving all common industrial control systems, such as Beckhoff, Siemens, Hitachi, Omron or Panasonic.

We develop in all common languages, such as FBD, LD, IL, ST, SFC, GRAPH and C++.

Integration and Industry 4.0

Connection to already existing ERP systems and databases. This creates new possibilities such as predictive maintenance.

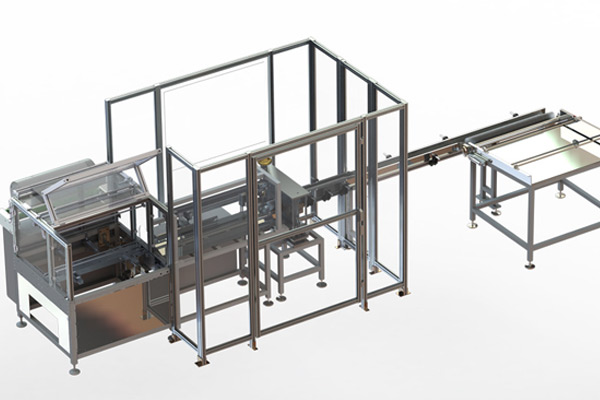

Engineering

We offer our services for tailor-made automation and special purpose machinery individually or in combination. We provide these services for individual tasks, complete machines and small production lines.

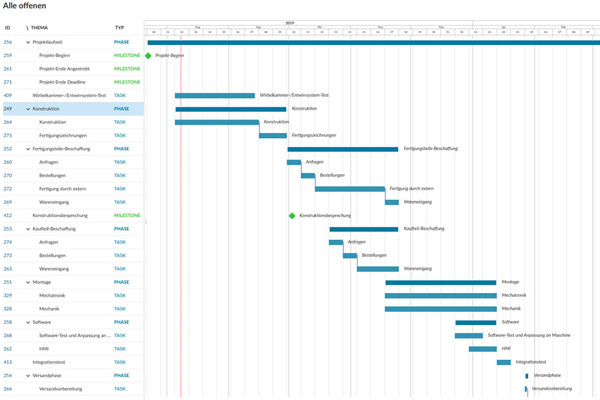

Project Management

For the successful implementation of a project we keep control during the complete project lifecyle:

- Complete process chain – from the conception to the commissioning

- Combination of classic Gantt-based scheduling for macro-management and modern agile Kanban for micro-management

- FMEA (failure mode and effect analysis)

Quality Management

- Electrical Test according to DGUV-V3

- Risk Assessment

- CE Evaluation

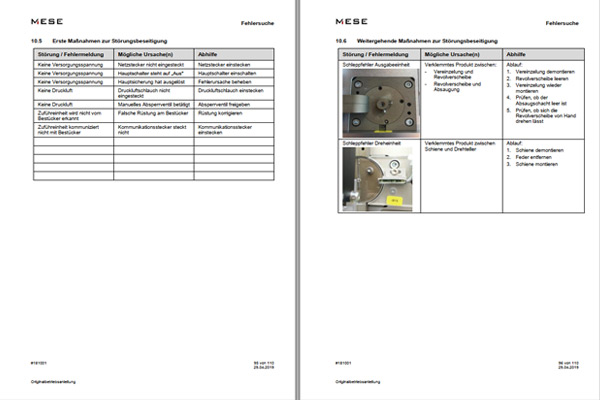

Technical Documentation

We prepare technical descriptions and explanations. These contain guidances for the following criteria:

- Safety Instructions

- Design and Function

- Handling and Operation

- Fault Identification and Troubleshooting

Maintenance and Repair

We repair and maintain both our own developments as well as developments of other companies, for example from China.

A comprehensive service in Germany and overseas goes without saying.

Benefit from our know-how

Solutions from the development to the commissioning.